In today's global manufacturing landscape, ensuring product safety and quality is non-negotiable—especially for industries like food, pharmaceuticals, and chemicals. Foreign object contamination not only damages brand reputation but also poses severe risks to consumer health and compliance with international standards. Now, we'll introduce UUPAC's High-Precision X-Ray Detector, which is designed to solve these kinds of troubles for you.

- Why X-Ray Detection Matters for Your Industry?

From food processing plants to pharmaceutical factories, the threat of foreign contaminants is omnipresent. Metal fragments, glass shards, stones, bones, or hard plastics can inadvertently enter products during manufacturing, leading to costly recalls, legal liabilities, and loss of customer trust.

UUPAC's High-Precision X-Ray Detectors are engineered to address these challenges head-on. Originally developed for medical safety, X-ray inspection technology has evolved into a cornerstone of industrial non-destructive testing, with applications spanning:

1. Food industry: Detecting contaminants in packaged foods, canned goods, and even delicate items like ham (where aluminum clamps and desiccants can be filtered out).

2. Pharmaceuticals: Ensuring drug purity by identifying foreign particles in tablets, capsules, or packaging.

3. Chemicals & materials: Inspecting raw materials and finished products for hidden defects.

4. General manufacturing: Supporting quality checks in footwear, wood processing, and more.

- Key Features of UUPAC High-Precision X-Ray Detectors

1. Superior Image Processing: With up to 8 grades of image processing, the system adapts to diverse products, ensuring stable and accurate detection across varying shapes, sizes, and packaging types. Whether inspecting bulk items or small, intricate products, you’ll get consistent results.

2. Advanced Contamination Filtering: The detector intelligently shields non-threatening elements like edges, desiccants, canned food lids, and even aluminum clamps on sausages—eliminating false alarms and focusing on real threats.

3. Global Safety Compliance: X-ray leakage levels meet strict US FDA and European CE standards, ensuring operator safety and compliance with international trade regulations—a critical factor for cross-border manufacturers.

4. Durable Design: Equipped with air conditioning for stable operation and an IP66 rating, the detector withstands harsh industrial environments, including dust, moisture, and temperature fluctuations.

5. Easy Maintenance: Designed for hassle-free dismantling and cleaning, minimizing downtime and keeping your production line running efficiently.

- Technical Specifications: Choose the Right Model for Your Needs

UUPAC offers a range of models to suit different production requirements, from compact setups to high-capacity lines. All models feature SUS304 food-grade stainless steel construction, a reject device with flash alarm, wired/USB data interfaces, and compliance with global safety standards.

At UUPAC, we specialize in intelligent manufacturing solutions—from combination weighing and packaging to conveying and detection. UUPAC's X-Ray Detectors are designed to integrate seamlessly with our existing equipment, creating a fully automated workflow:

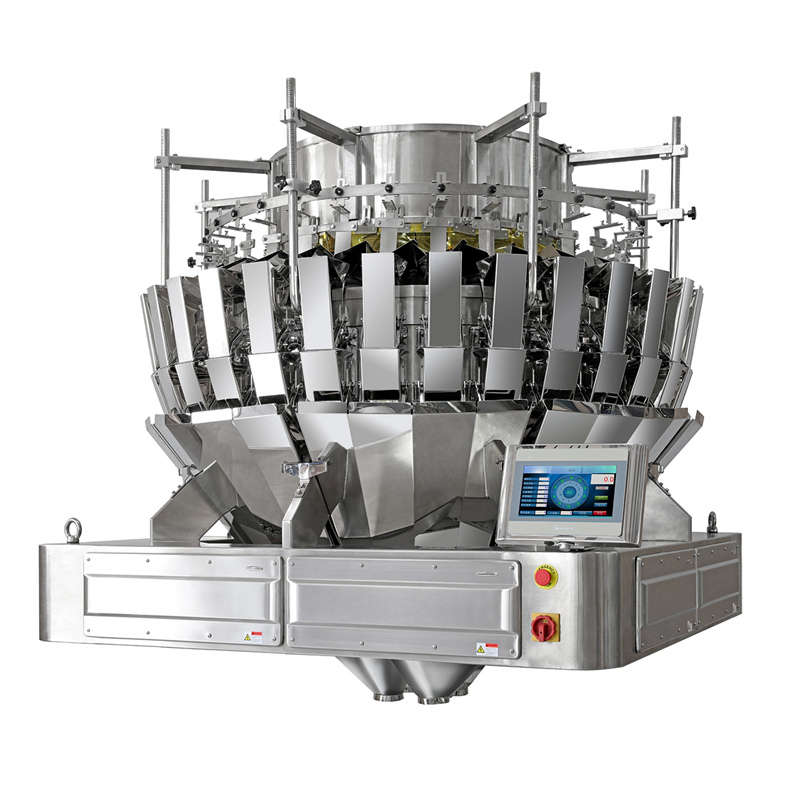

- Pair with our multihead weighers for precise portioning followed by contaminant checks.

- Connect to smart packaging lines to ensure sealed products are free of defects.

- Sync with conveyor systems for continuous, high-speed inspection without bottlenecks.

This integration not only enhances efficiency but also reduces manual intervention, lowering the risk of human error and ensuring consistent quality across your production chain.

- Why Choose UUPAC for Your X-Ray Detection Needs?

For equipment buyers, reliability, compliance, and after-sales support are paramount. UUPAC's High-Precision X-Ray Detectors deliver on all fronts:

1. Global Compliance: Meets FDA and CE standards, simplifying market access in North America, Europe, and beyond.

2. Proven Performance: Trusted by manufacturers in food, pharmaceuticals, and chemicals for its accuracy and durability.

3. Easy Maintenance: IP66 rating and detachable components make cleaning and upkeep straightforward, even in demanding environments.

4. Customizable Solutions: With a range of models, we can tailor the detector to your specific production line size and throughput.

Don't let foreign object contamination compromise your products or brand. UUPAC's High-Precision X-Ray Detector offers the precision, safety, and integration capabilities modern manufacturers need to stay ahead. Ready to elevate your quality control? Please contact us for more information.