In industrial piping systems, the gate valve is one of the most widely used valves. Its key advantage lies in providing either a fully open flow path or a complete shutdown, ensuring excellent sealing performance with minimal pressure drop. Because of this, gate valves are regarded as the “gatekeepers” of safe system operation in critical industries such as power generation, petrochemicals, water treatment, marine, and natural gas.

A common question from customers is: Why must gate valves be used for shutdown in certain critical pipelines? What makes them stand out? Let’s break it down in simple terms.

1. How a Gate Valve Works: As Simple as Opening or Closing a Door

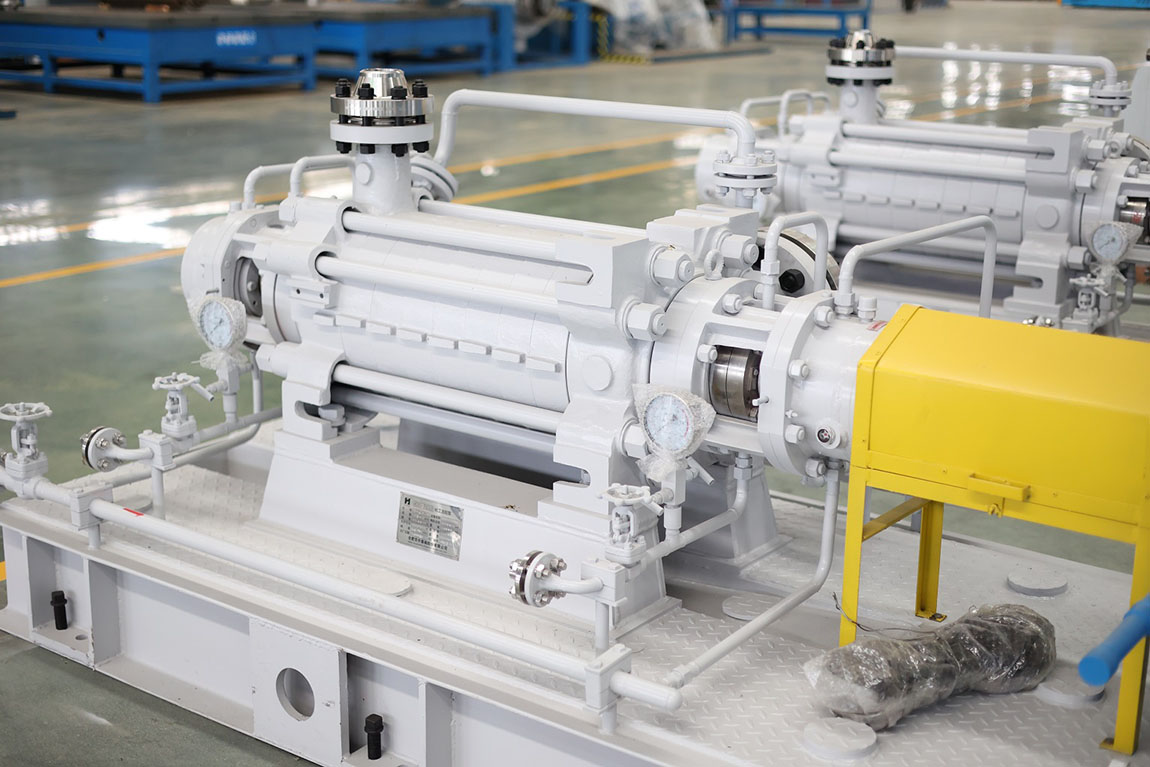

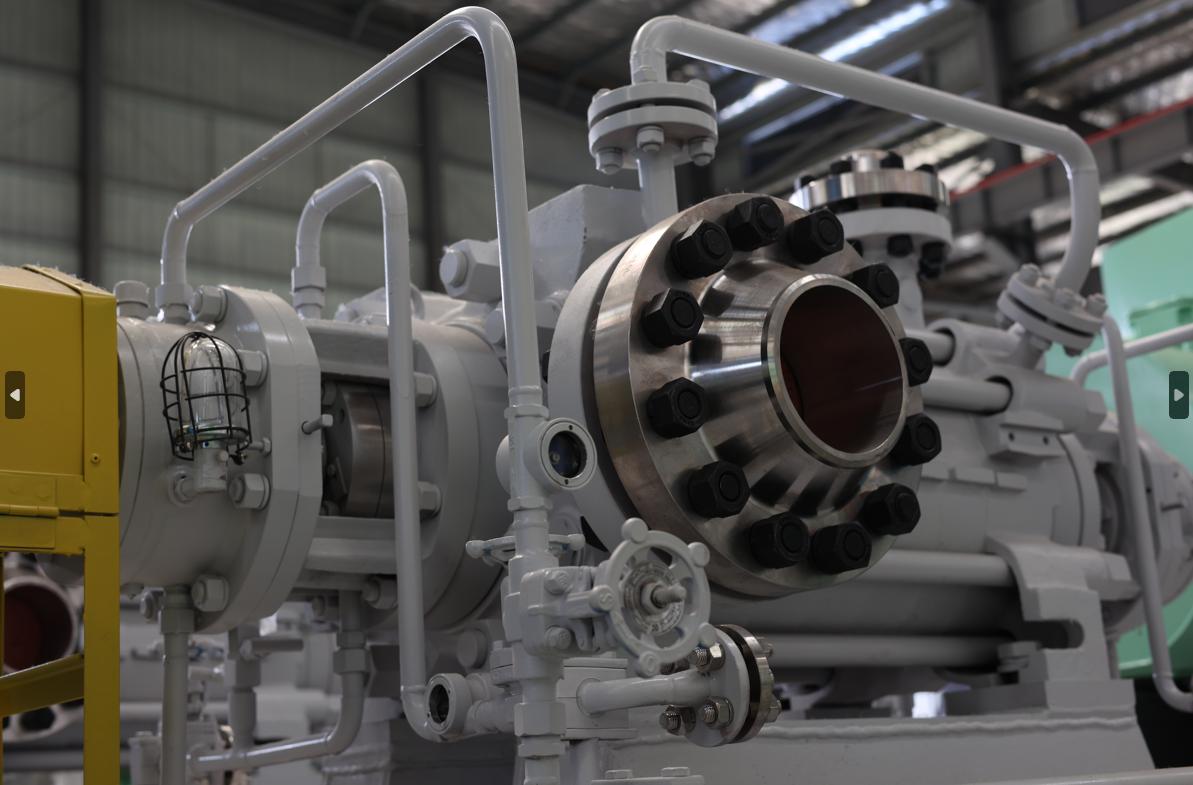

The disc of a gate valve functions much like a door. When lifted, the flow inside the pipeline remains unobstructed; when lowered, the flow is completely blocked.

● Compared with ball valves, gate valves are better suited for large-diameter and high-pressure applications.

● Compared with butterfly valves, gate valves provide stronger sealing when fully closed, often achieving “zero leakage” or close to it.

Think of it like your home’s front door. When shut, it keeps outside air and noise almost entirely out—that’s the reliable shutdown of a gate valve. A screen door, though lighter and easier to use, doesn’t seal nearly as well, similar to the characteristics of butterfly valves under certain conditions.

2. Why Are Gate Valves Essential in Critical Systems?

In systems where safety and sealing reliability are paramount, the role of gate valves becomes especially critical:

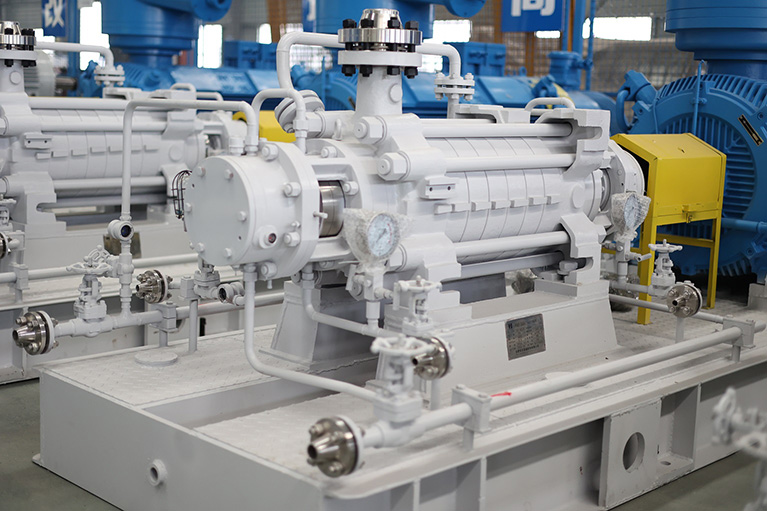

● Oil Pipelines: During long-distance crude oil transportation, any leakage can lead to severe environmental damage and significant economic loss. Gate valves can provide rapid shutdown in emergencies, preventing further escalation.

● Power Plant Cooling Systems: When a unit requires an emergency shutdown or maintenance, gate valves ensure a complete cutoff of cooling water, safeguarding equipment.

● Natural Gas Transmission: The high pressure and flammability of natural gas demand valves with absolute sealing reliability. In these cases, gate valves serve as the critical safeguard.

These examples highlight the true value of gate valves: they are not just “flow control devices,” but essential barriers that protect the entire system’s safety.

3. Advantages of Gate Valves

● Reliable Shutoff Performance: When fully closed, gate valves provide near-zero leakage, ensuring complete isolation of the medium.

● Wide Applicability: Suitable for high-temperature, high-pressure, and large-diameter applications.

● Low Flow Resistance: Once the gate is lifted, the passage is almost straight, allowing fluid to flow with minimal resistance.

● Cost-Effective Maintenance: With proper selection and regular inspection, gate valves often have a longer service life compared to other valve types.

4. Understanding Gate Valves in Everyday Life

Although we rarely see industrial gate valves directly in daily life, we can relate to them through familiar examples.

● Main Water Shutoff Valve: When building maintenance requires pipeline work, closing the main valve stops water supply to the entire building. This is very similar to a gate valve’s function—completely isolating the fluid to ensure the safety of subsequent operations.

● Manual Gas Valve: The hand-operated valve before a gas meter is a small-scale shutoff device, designed to quickly stop gas flow in case of a safety hazard.

5. How to Ensure the Reliability of Gate Valves

● Proper Selection: Choose materials suitable for the medium’s temperature, pressure, and corrosiveness (e.g., WCB, F304, F316).

● Correct Installation: Ensure the valve body is concentric with the pipeline to avoid stress concentration.

● Proper Operation: Avoid keeping the valve half-open; gate valves are designed primarily for fully open or fully closed positions.

● Regular Inspection: Focus on the stem seal, packing, and valve seat wear.

Conclusion

With their reliable shutoff performance, gate valves play a vital role in critical systems such as oil and gas, power generation, and municipal infrastructure. They act as the system’s “gatekeeper,” ensuring safety and stability when it matters most. Proper selection and usage of gate valves not only improve operational reliability but also reduce maintenance costs and operational risks.

Frequently Asked Questions (Q&A)

Q1: Can gate valves be used to regulate flow?

A: Gate valves are mainly intended for fully open or fully closed operation and are not suitable for flow regulation. Long-term operation in a half-open position can cause disc erosion and damage the sealing surface.

Q2: Which is better, a gate valve or a ball valve?

A: There is no absolute “better” choice; it depends on the application. Ball valves operate quickly and are suitable for small-diameter, frequent operation; gate valves are preferred for large-diameter, high-pressure systems where reliable shutoff is required.

Q3: How long does a gate valve typically last?

A: With proper selection and maintenance, the service life of a gate valve is usually over 10 years. Some metal-seated models can even last up to 20 years.

Q4: What do customers often overlook when purchasing gate valves?

A: Many focus only on price and overlook material and sealing design. In reality, choosing the right materials and proper design are the key factors determining a gate valve’s longevity and reliability.