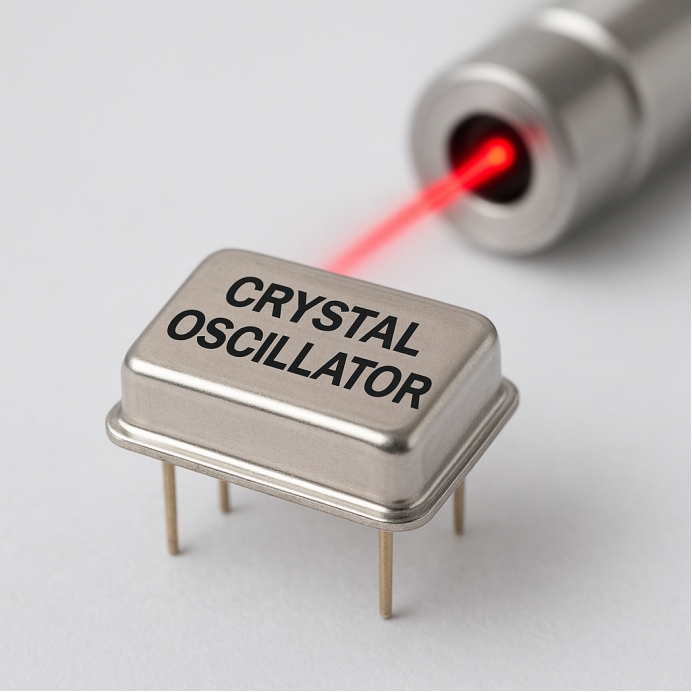

In modern laser systems, precision and stability are the foundation of performance. Whether in industrial laser cutting, optical communication, or medical laser applications, each pulse of light must be precisely timed and synchronized. At the core of this timing accuracy lies one key component — the crystal oscillator.

A crystal oscillator is an electronic component that generates a stable frequency signal by utilizing the mechanical resonance of a quartz crystal. In laser equipment, this frequency serves as a reference clock, ensuring consistent timing and synchronization across multiple control modules. Without such precise frequency control, even the most advanced laser systems would experience instability, reduced beam quality, or synchronization errors.

The Core Function of the Crystal Oscillator in Laser Devices

In laser systems, especially those operating in high-frequency or pulsed modes, timing control is critical. The crystal oscillator circuit provides the necessary frequency reference that determines how and when the laser diode or Q-switch operates.

For example, in a pulsed laser, the timing between the trigger signal and the laser pulse must be maintained within nanoseconds. A low-jitter crystal oscillator ensures that each pulse is fired at exactly the right interval, enabling uniform energy output and consistent beam shape. Any deviation in the oscillator’s frequency could lead to inconsistent pulse intervals, directly affecting cutting precision or marking accuracy in industrial applications.

Frequency Stability and System Synchronization

Laser systems often integrate multiple subsystems — including power drivers, optical control circuits, and feedback loops. The frequency stability of the crystal oscillator ensures that all these subsystems work in harmony.

For instance, in fiber laser systems, the optical amplifier, modulator, and feedback sensor must operate in perfect synchronization. The temperature-compensated crystal oscillator (TCXO) or oven-controlled crystal oscillator (OCXO) helps maintain frequency stability despite environmental fluctuations, such as changes in temperature or vibration. This stability translates into higher beam coherence, improved energy efficiency, and enhanced long-term operational reliability.

Enhancing Laser Modulation and Control Accuracy

Laser modulation — whether in continuous-wave or pulsed mode — requires precise control of the modulation frequency. Crystal oscillators serve as the frequency reference for signal generators and timing controllers that define the laser’s operating parameters.

In communication lasers or LIDAR systems, where data transmission or distance measurement depends on high-frequency modulation, high-precision oscillators ensure the signal’s integrity and minimize phase noise. A small phase deviation can cause signal distortion or reduced detection accuracy. Therefore, using a low phase-noise crystal oscillator directly enhances the system’s signal-to-noise ratio (SNR) and overall performance.

Application in Industrial and Medical Laser Systems

In industrial laser cutting and marking machines, crystal oscillators help control the pulse repetition rate and timing accuracy of laser emission. Stable timing enables cleaner edges and higher repeatability in automated manufacturing.

In medical lasers, such as those used for eye surgery or skin treatments, precision is even more critical. The oscillator’s frequency determines the exact timing of each pulse, ensuring minimal thermal damage to surrounding tissue. These systems often integrate temperature-compensated oscillators to maintain accuracy during long operation cycles.

Future Trends: Integration with AI and Smart Control Systems

As laser systems evolve toward intelligent automation and precision manufacturing, crystal oscillators are adapting to meet new requirements. The rise of AI-assisted laser control and high-speed data feedback demands even tighter synchronization between digital processors and optical emitters.

Modern oscillators are being designed with ultra-low jitter, miniaturized form factors, and enhanced electromagnetic compatibility (EMC). In smart manufacturing environments, these features allow for real-time performance monitoring and adaptive frequency tuning, ensuring optimal laser efficiency under varying conditions.

The crystal oscillator may appear to be a small and simple component, yet it serves as the heartbeat of modern laser equipment. By providing a stable and precise timing source, it ensures synchronization, accuracy, and consistency across all stages of laser operation — from modulation and emission to feedback and control.

As laser technology continues to expand into fields such as precision medical equipment, advanced communication systems, and intelligent manufacturing, the importance of high-quality crystal oscillators will only increase. Their contribution to frequency stability, system synchronization, and signal integrity makes them an irreplaceable element in the pursuit of laser precision and performance.