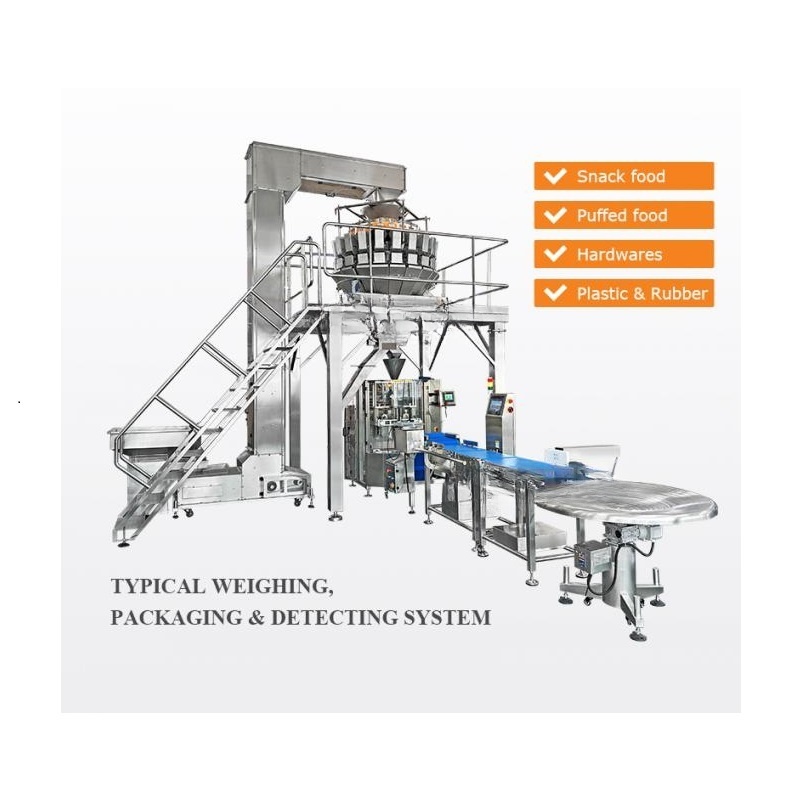

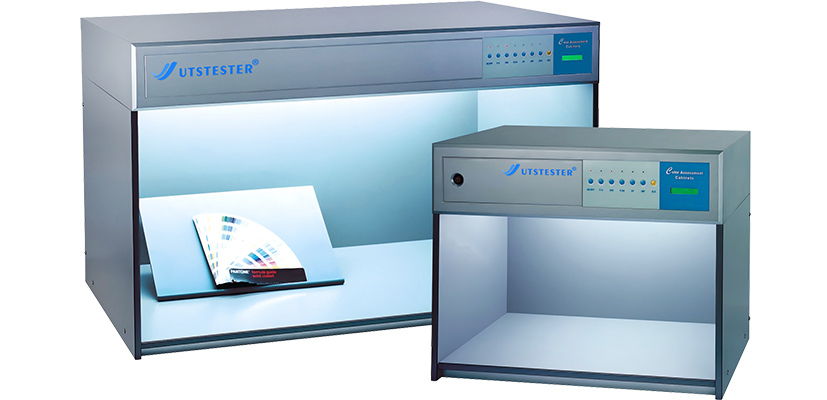

For manufacturers dealing with granular, irregular, or small-batch products—from nuts and candies to hardware fasteners and frozen dumplings—production bottlenecks often hide in the gap between weighing and packing. Traditional separate processes (e.g., manual weighing + semi-automatic packing) lead to slow throughput, inconsistent weights, and wasted labor. But a well-designed high-speed weighing and packing system, like UUPAC's Typical Weighing Packing Checking & Detecting Solution, integrates these steps into a seamless workflow. This guide breaks down how such systems boost output, their key components, real-world applications, and how to choose the right one for your production line.

1. First: What Products Benefit Most from UUPAC's System?

A high-speed weighing and packing system isn't a "one-size-fits-all" tool—it shines when paired with products that demand speed and precision. UUPAC's solution is tailored to 4 core product categories, covering most high-volume production needs:

- Snacks & Dried Foods: Nuts (walnuts, almonds, pistachios), dried fruits (blueberries, red dates, raisins), candies, popcorn, potato chips, and pasta. These products often require gentle handling (to avoid breakage) and precise portioning (to cut overpack waste).

- Pet Food: Granular or small-bite pet food, where consistency in each pack ensures customer trust and reduces material costs.

- Frozen Foods: Dumplings, chicken wings, glutinous rice balls, and beef balls. The system's stable operation handles cold, slightly sticky frozen products without jams.

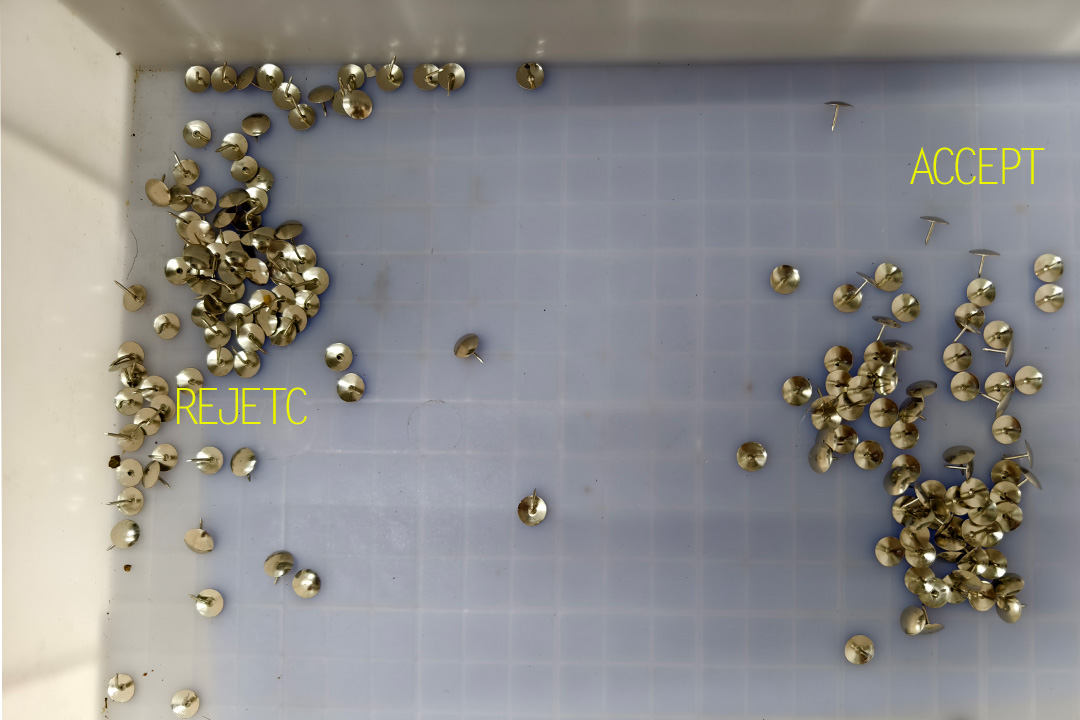

- Hardware & Plastics: Small metal items (nails, bolts, screws, rivets) and plastic particles. These products need accurate counting + weighing to avoid underpacking (which risks returns) or overpacking (which wastes materials).

This wide applicability means you won't need separate systems for different product lines—one UUPAC setup can switch between snacks and hardware with simple adjustments.

2. 3 Core Ways UUPAC's System Maximizes Your Output

The goal of a high-speed weighing and packing system is to eliminate delays, reduce errors, and keep your line running smoothly. UUPAC's solution achieves this with 3 design-driven advantages:

① Fully Coordinated Automatic Control (No More "Wait Time")

Traditional lines often have mismatched speeds: a weigher that can handle 60 packs/min paired with a packager that does 80 packs/min, or vice versa—creating backlogs. UUPAC's system uses centralized control to sync every step:

It starts with auto-feeding (via the Z-type bucket conveyor) that adjusts to the weigher's speed, so there's no product shortage or overflow.

If no packaging bags are detected, the system pauses filling and sealing automatically ("no bags, no fill")—avoiding product spills and rework.

② Stable Operation + Low Energy Use (Less Downtime)

Downtime kills output. UUPAC's system minimizes stops with:

- A balanced working platform: The design keeps the weigher, packager, and conveyors aligned, reducing vibration that causes jams or inaccurate weights. This stability means the system can run 8+ hours continuously without manual adjustments.

- Energy-efficient components: The system uses only as much power as needed (e.g., slowing feeders when the weigher's hoppers are full), cutting electricity costs by 15% compared to older, less efficient setups.

③ Wide Weighing Range + High Accuracy (No Wasted Product)

Output isn't just about speed—it's about producing sellable packs. UUPAC's system uses a 10/14 Head Computer Weigher (the core of the setup) to deliver:

- A large weighing range: It handles small portions (e.g., 5g of candy) to larger batches (e.g., 500g of whole grains), so you don't need a separate weigher for different pack sizes.

- Precise weighing: The multi-head design combines weights from independent hoppers to hit target weights with minimal error, reducing overpack waste.

3. Breakdown of UUPAC's System Components (What Makes It Work)

UUPAC's Typical Weighing Packing System is built from 5 essential units (plus 2 optional detectors) that work together to maximize efficiency. Each part has a clear role in keeping the line moving, and their coordination ensures no bottlenecks:

① Z-type Bucket Conveyor

② 10/14 Head Computer Weigher

③ Working Platform

④ VFFS (Vertical Form-Fill-Seal Machine)

⑤ Finished Product Conveyor

⑥ Optional Automatic Check Weigher

⑦ Optional Metal Detector/X-Ray Detector

Conclusion

A high-speed weighing and packing system isn't just an equipment upgrade—it's an investment in higher output, lower waste, and less stress. UUPAC's Typical Weighing Packing System stands out because it's designed for real-world production needs: wide product compatibility, stable operation, and flexible components that grow with your business.

If you're tired of production line slowdowns, contact us to learn how our system will maximize your output.