From smartphones to computers, from smart home devices to industrial automation control systems, the performance and reliability of electronic products are under intense scrutiny. However, throughout their entire lifecycle, these products inevitably encounter diverse climatic conditions—such as high temperatures, low temperatures, high humidity, and temperature-humidity fluctuations. These environmental factors can severely impact electronic products' performance, lifespan, and reliability, even leading to product failures.

Environmental test chambers serve as the core equipment to address this challenge and fortify product quality defenses.

The operational environments for electronic products and materials are complex and variable—from tropical high-temperature/high-humidity conditions to frigid low-temperature regions, from coastal salt fog corrosion to thermal shock during transportation. Any extreme condition can potentially trigger performance failures. Conventional testing can only verify product performance under standard conditions, failing to predict potential risks in real-world use. Environmental test chambers artificially simulate these complex environments, compressing months or even years of natural aging into days or weeks, thereby completing reliability verification in advance.

I. Core Environmental Testing for Electronics

Temperature Cycling

Temperature cycling examines equipment response to repeated shifts between hot and cold conditions. It effectively identifies solder cracks, seal failures, and material expansion issues. Chambers with precise temperature control ensure each cycle is repeatable and traceable.

Humidity Testing

Humidity affects internal circuits, materials, and adhesives. Testing under high humidity reveals early signs of corrosion or moisture ingress. Cantrol chambers specialize in consistent humidity control to support these tests.

Stable chambers maintain consistent environmental conditions, supporting extended test cycles—particularly when products require prolonged exposure to high temperatures or humidity.

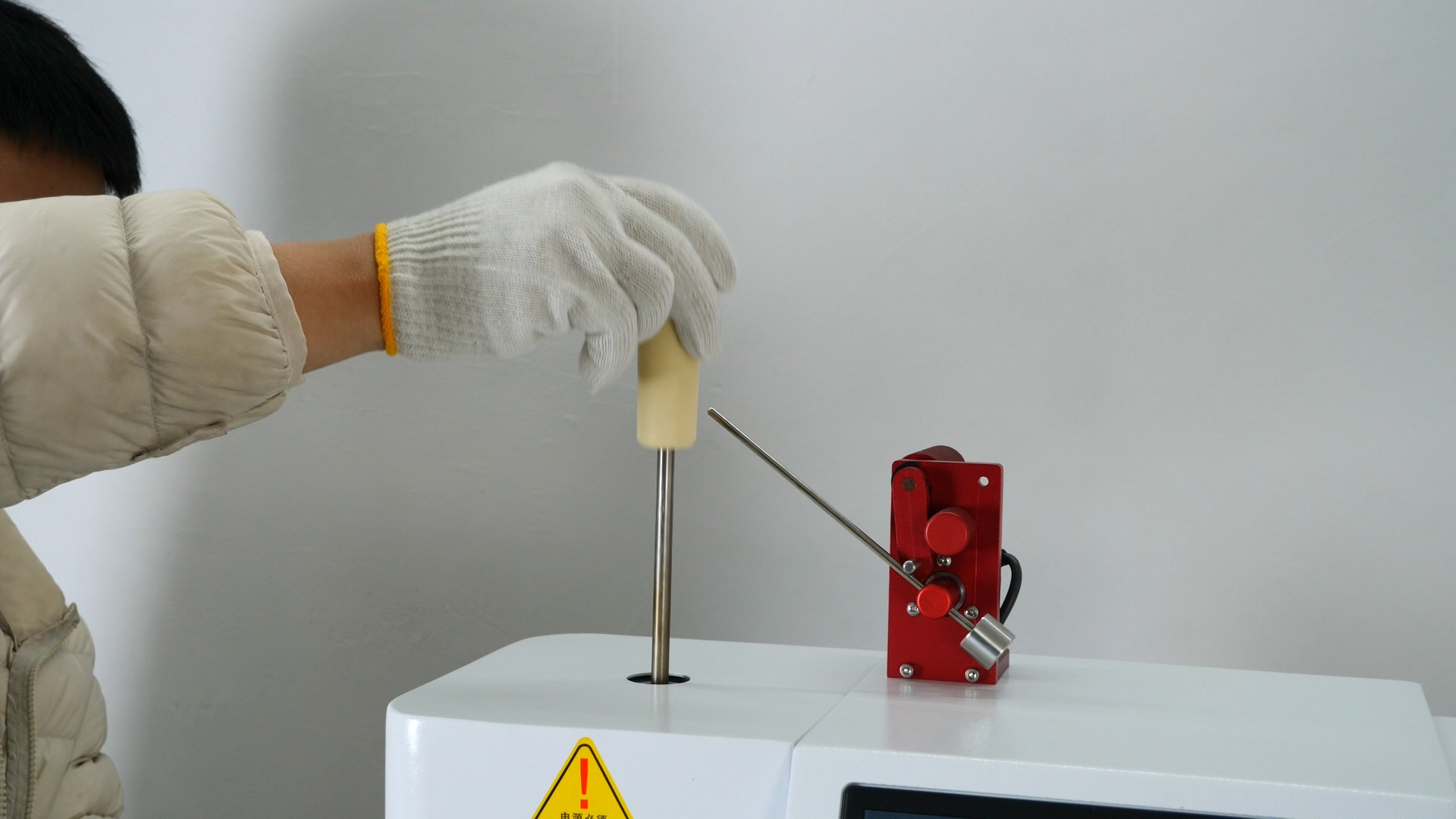

Constant Temperature and Humidity Chamber for Product Testing

Thermal Shock

Thermal shock subjects equipment to rapid fluctuations between extreme heat and cold. This test simulates real-world events like moving from indoor environments to cold outdoor air. Results show how well materials withstand stresses caused by sudden expansion and contraction.

Vibration and Shock

Mechanical vibration testing examines electronics' endurance during transport, operation, or long-term use. Shock testing simulates impact events like accidental drops or device collisions. These tests help confirm mechanical stability.

Altitude Testing

Altitude chambers simulate low-pressure environments during air transport or high-altitude operations. This testing is particularly valuable for products containing batteries or sealed enclosures.

Dust and Ingress Testing

Certain electronics require dust resistance or general protection. Dust testing ensures particles cannot penetrate sensitive areas. Results help companies achieve IP ratings when required.

II. Mainstream Environmental Test Chamber Types and Application Scenarios

1. Climatic Environment Type (Salt Spray, Humidity/Heat, High/Low Temperature): Simulates climate conditions such as temperature/humidity, salt spray, and UV radiation to test material corrosion resistance and aging performance.

Typical Application Scenarios: Coastal electronic equipment, outdoor communication terminals, polymer material enclosures

2. Mechanical Environment Type (Vibration, Shock, Drop): Simulates mechanical stresses like vibration, transient impacts, and free falls to validate structural strength and component connection reliability.

Typical Applications: Automotive electronics, consumer electronics, aerospace components

3. Combined Environmental Testing (Triple-Combined, Temperature-Salt Spray Combined):

Multi-factor coordinated simulation to replicate complex environmental stresses encountered in real-world scenarios.

Typical Applications: Naval electronics, high-end semiconductors, new energy equipment

III. The Importance of Climate Chamber Testing in Electronic Products

(A) Simulating Extreme and Real-World Environments

1. High-Temperature Environment Simulation and Its Impact on Electronic Products

In high-temperature environments, electronic components inside products face severe challenges. For instance, semiconductor device performance may drift with rising temperatures, causing unstable circuit parameters. Excessive heat also accelerates component aging, shortening their lifespan. Take computer CPUs as an example: prolonged operation in high temperatures may cause inadequate heat dissipation, triggering automatic throttling to protect the chip and significantly reducing system performance. In severe cases, this can even cause permanent damage to the CPU.

2. Low-Temperature Environment Simulation and Consequences

Low temperatures also pose challenges for electronic products. Certain materials become brittle in cold conditions—plastic casings may crack, compromising product aesthetics and protective integrity. For battery-powered electronics, low temperatures significantly reduce battery activity and shorten battery life. For instance, smartphone battery life often noticeably decreases during cold winters, illustrating the direct impact of low temperatures on battery performance.

3. Challenges in High-Humidity Environments

High humidity ranks among the greatest enemies of electronic products. Moisture can form conductive pathways on circuit boards, causing short circuits and sudden failures. Simultaneously, high humidity accelerates corrosion of metal components such as connectors and wires within electronic devices. Corrosion increases contact resistance, degrades signal transmission quality, and ultimately leads to diminished product performance or failure.

4. Testing Product Structure and Functionality Under Temperature and Humidity

In practical use, electronic products frequently encounter alternating temperature and humidity conditions—such as transitioning from cold outdoor environments to warm, humid indoor spaces. These rapid temperature and humidity shifts induce thermal expansion and contraction stresses within the product, threatening its structural integrity. For instance, in poorly sealed electronic devices, moisture may infiltrate during these cycles, damaging internal components or causing severe issues like circuit board delamination through repeated exposure.

(2) Testing Product Reliability and Stability

1. Long-Term Exposure Testing to Determine Product Lifespan and Durability

The lifecycle of electronic products in actual use can be approximated through prolonged simulated environmental exposure testing in climate chambers. For instance, placing a batch of electronic products in a climate chamber set to high-temperature and high-humidity conditions for several months allows observation of changes in performance metrics—such as failure rates or performance degradation rates—providing scientific basis for warranty period setting and reliability assessment.

2. Cycling Tests to Evaluate Adaptability Across Environmental Transitions

Temperature-humidity cycling tests effectively assess an electronic product's adaptability during frequent switching between different environmental conditions. For instance, certain outdoor electronic devices must operate stably under conditions of high daytime temperatures, low nighttime temperatures, and significant humidity fluctuations. By simulating these temperature-humidity cycles in a climate chamber and observing performance changes after multiple cycles—such as whether the product boots normally or retains full functionality—the product's environmental adaptability and reliability can be determined.

Conclusion

Whether in consumer electronics, automotive new energy, or other civilian sectors, or in aerospace, defense, and other high-end manufacturing fields, environmental test chambers have become the core support for product reliability testing. They serve not only as “detectors” for identifying defects but also as ‘passports’ for compliance certification and “optimizers” for cost control. Amid the industry trend toward pursuing high-quality development, precise environmental simulation testing is the essential path for electronic products and materials to establish themselves in the market and earn trust.

Email: hello@utstesters.com

Direct: + 86 152 6060 5085

Tel: +86-596-7686689

Web: www.utstesters.com