Introduction

The direct-cooling block ice machine is a highly efficient refrigeration machine that finds widespread application of the ice machine for fishery, food processing, and supermarket industries. In this article, we will provide you with a comprehensive guide on how to choose a direct-cooling block ice machine that offers excellent value for money and quality.

Understanding the Principles and Features of Direct-Cooling Block Ice Machines

Direct-cooling block ice machines operate by directly absorbing heat using refrigerant, allowing water to freeze into ice blocks within the ice mold. These machines possess several key features:

- Fast ice production with high-quality ice blocks;

- Energy-efficient and environmentally friendly, resulting in low operational costs;

- Simple structure for easy maintenance;

- Wide application range, customizable ice block sizes according to specific needs.

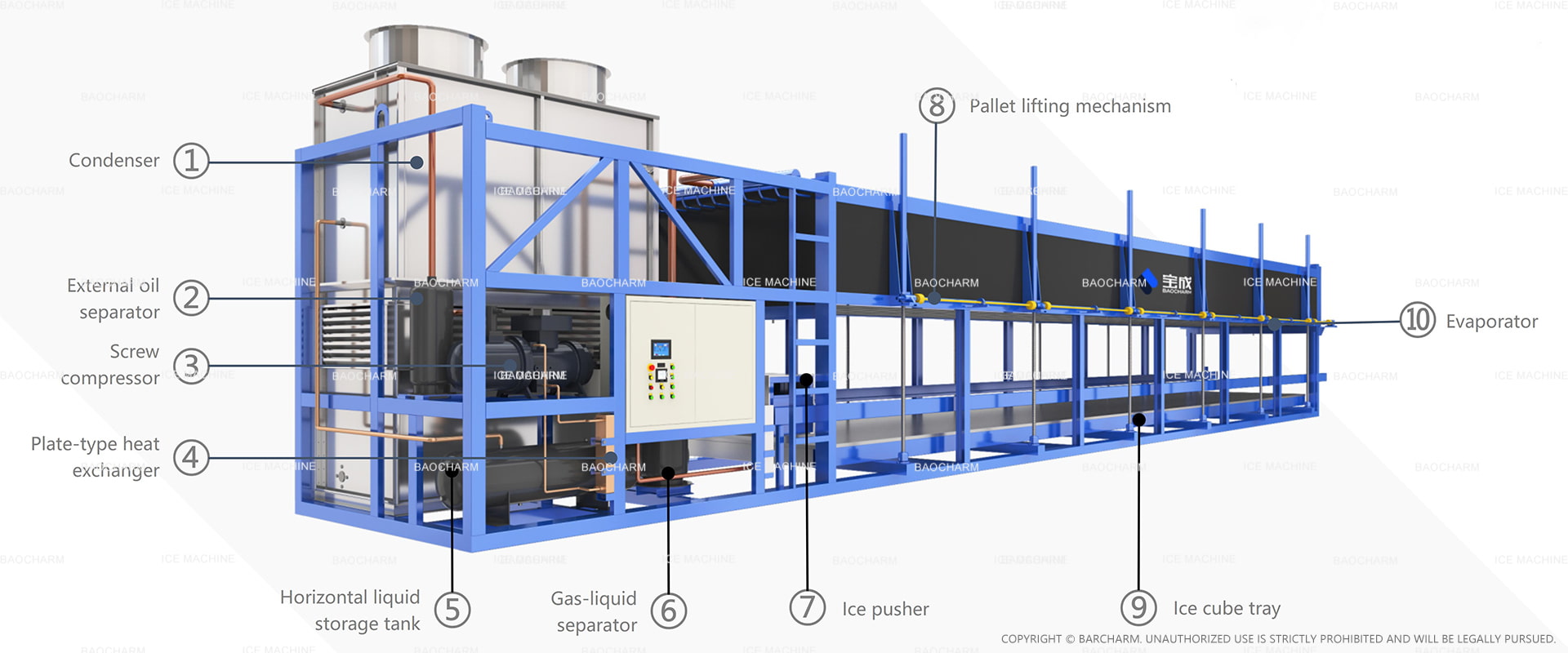

Understanding the Main Components of a Direct-Cooling Block Ice Machine

Before diving into the nuances of selecting a direct-cooling block ice machine, it is crucial to grasp the fundamental components that make up these machines. Each component plays a pivotal role in the machine’s operation, and understanding their functions is essential for making an informed purchase decision.

- Ice Machine Compressor: The heart of the direct-cooling block ice machine, the compressor is responsible for pumping the refrigerant through the system. It facilitates the transfer of heat, allowing the refrigerant to absorb heat from the water and convert it into ice. The compressor’s efficiency directly impacts the machine’s ice production rate and energy consumption.

- Ice Machine Evaporator (Ice Block Mold): The evaporator is where the refrigerant absorbs heat from the water, leading to the formation of ice blocks. The design and quality of the evaporator are critical to the machine’s overall performance. In a direct-cooling block ice machine, the ice block mold shapes the ice blocks, and it’s essential to select a mold that meets your specific requirements and desired ice block size.

- Ice Machine Condenser: The condenser is responsible for removing heat from the refrigerant after it has absorbed heat from the water. There are several types of condensers, including water-cooled, air-cooled, and evaporative cooling condensers. Each type has its advantages and is suitable for different environments and applications.

- Ice Machine Control System: The control system is the brain of the machine, managing all operations. It includes the water supply system, refrigeration system, and the automatic ice ejection system. A well-designed and precise control system ensures smooth operation, optimal performance, and safety.

- Ice Machine Mechanical System: The mechanical system includes the tray lifting system and the ice pushing system. The tray lifting system allows for easy loading and unloading of ice blocks, while the ice pushing system automates the process of moving ice blocks from the machine to storage or the desired location.

- Ice Machine Frame and Ice Tray: The frame provides the structural support for the entire machine, ensuring stability and durability. The ice tray holds the water that will freeze into ice blocks, and its design is crucial for efficient ice production and easy ice retrieval.

Key Considerations for Choosing a Direct-Cooling Block Ice Machine

- Ice Production Capacity: Determine the required ice production capacity based on your ice maker machine for business needs. Larger ice production capacities often come with higher costs, so it is crucial to strike a balance between capacity and budget.

- Ice Block Size: Direct-cooling block ice machines come in various ice block sizes, such as 5KG, 25KG, 50KG, and 100KG. Choose a size that aligns with your intended use.

- Brand and After-Sales Service: Opt for a reputable brand known for quality and reliability. Additionally, consider the after-sales service, including warranty periods, maintenance, and repair services.

- Efficiency: Look for machines with high ice production efficiency and low energy consumption. Factors affecting efficiency include machine power, ice mold design, and the quality of the compressor and evaporator.

- Safety: Ensure the machine has safety features such as overload protection and short-circuit protection to guarantee safe operation.

Additional Considerations for Optimal Selection

- Industry Trends: Stay updated on the latest developments in the direct-cooling block ice machine industry, including new models and technologies. This knowledge will help you make informed decisions during the selection process.

- Manufacturer Background: Investigate the manufacturer’s background, including the ice machine china company history, production facility size, R&D capabilities, equipment quality and stability, energy consumption ratio, export and transportation experience, and more.

Conclusion

Choosing a direct-cooling block ice machine is a multifaceted task that requires careful consideration. By understanding the principles and features of these machines, comparing their advantages, and selecting a reputable manufacturer with a strong track record, you can secure a high-quality, cost-effective direct-cooling block ice machine that meets your business needs.

Baocharm: Your Trusted Partner in Ice Making

Having navigated the complexities of direct-cooling block ice machines, it is clear that Baocharm stands out as a manufacturer that not only understands the intricacies of ice production but also prioritizes customer satisfaction. Our reputation for providing high-quality, cost-effective solutions is built on years of experience and a commitment to excellence.